Pneumatic Muffler Silencer

Ningbo QM Pneumatic Components Factory was founded in 2014, is a focus on the development of pneumatic tools products, production and sales of modern enterprises. The factory is located in Ningbo, covers an area of more than 1000 square meters, has advanced production equipment and high-quality professional personnel team.

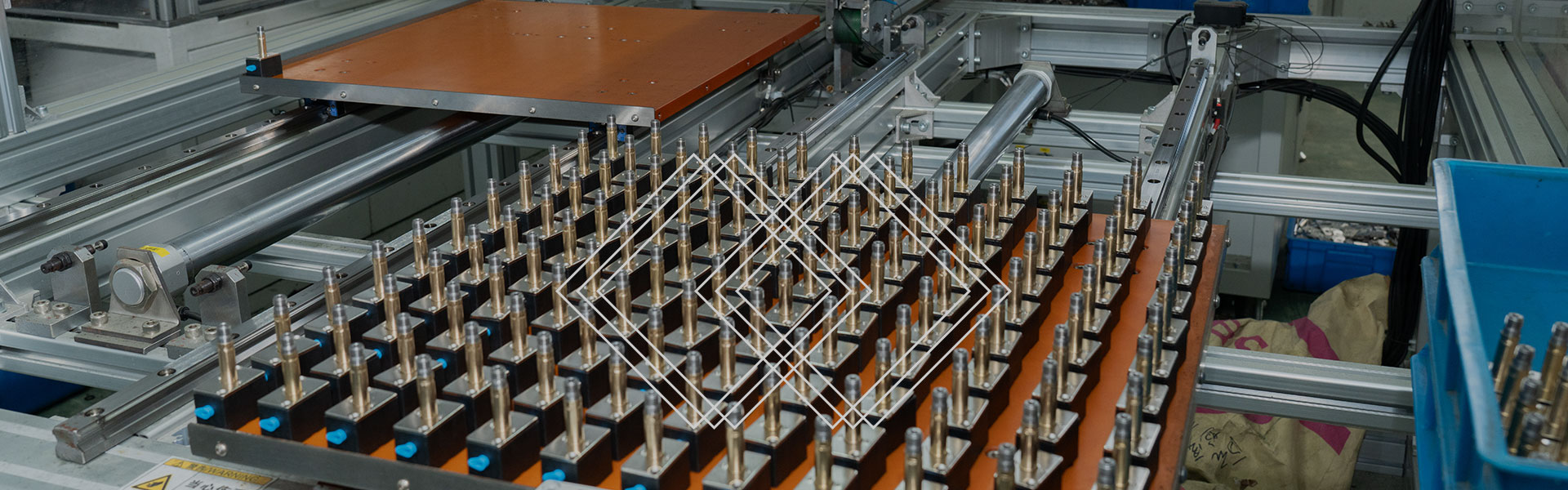

Our factory has introduced advanced automated production lines, which greatly improves production efficiency and reduces production costs, making our products highly competitive in the market.

In terms of research and development, the factory has an experienced and innovative R & D team, which constantly pays attention to market demand and industry development trends, and is committed to developing silencer products with better performance and a wider range of applications. At present, our products cover many fields such as automotive silencers, industrial silencers, and household silencers, which can meet the individual needs of different customers.

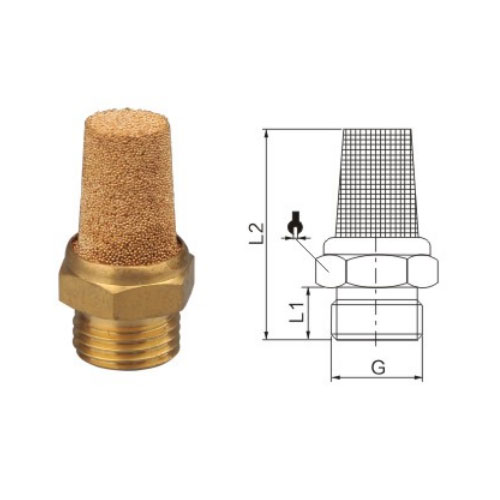

A Pneumatic Muffler Silencer is a device used to reduce airflow noise in a pneumatic system.

Its working principle is usually to reduce the speed and pressure fluctuations of the air stream by changing the flow characteristics of the air stream, such as increasing the length of the air stream channel, changing the cross-sectional area, setting a buffer structure or using sound absorbing materials, so as to reduce the generation and propagation of noise.

Common types of Pneumatic Muffler Silencer include:

1. Resistant silencer: mainly relies on the mutation of the pipeline section or the structure of the adjacent resonator, so that the sound wave is reflected and interfered in the propagation process to eliminate the sound.

2. Resistive silencer: The use of sound absorbing materials to absorb sound energy to reduce noise.

When selecting a Pneumatic Muffler Silencer, factors such as operating pressure, flow rate, noise frequency characteristics, installation space, and cost need to be considered. Its advantage is that it can effectively reduce the operating noise of the pneumatic system, improve the working environment, and reduce the impact of noise on the surrounding environment.

For pneumatic components and various accessories, we have accumulated a lot of technical experience and know-how in long-term production practice, and can quickly solve various problems encountered in the production process, and ensure the stability of product quality. We use modern production equipment and automated production lines to improve production efficiency and product accuracy, and reduce labor costs and error rates. From the screening of raw materials to the testing of finished products, each process has strict quality control standards to ensure the performance and reliability of the silencer. Through scientific production planning and scheduling, reasonably arrange the production process, reduce the production cycle, and improve the timeliness of order delivery. The advantages of all factories have enabled us to accumulate customers from all over the world, such as the United States, South Korea, France, Japan, Egypt, etc., and have obtained good customer feedback.

- View as

Metal Muffler Silencer

The noise by expanding the chamber and interference principle. First the exhaust air enters the expanding chamber of the muffler, the gas volume suddenly increases, and the airflow speed decreases, resulting in the change of the propagation characteristics of the sound wave. Secondly, the special structure inside of Metal Muffler Silencer will cause the sound wave to reflect and interfere. Thus achieve the effect of reducing noise.

Read MoreSend Inquiry