2 Position 2/2-way Solenoid Valves

The 2 position 2/2-way Solenoid Valves are a common type of solenoid valve. It has two working locations and two channels. At a working position, the channel is open to allow fluid to pass through; When in another working position, the channel is closed, preventing fluid flow.

Send Inquiry

2 position 2/2-way Solenoid Valves work through the role of electromagnetic force to control the position of the valve core, so as to achieve the valve conduction and cut-off. When the solenoid is energized, the resulting magnetic force attracts the spool, causing it to move to a position that opens or closes the fluid channel; When the electromagnetic coil is powered off, the spool returns to the initial position under the action of the spring force or other restoring force to change the channel state.

Product No.: NC255 Series solenoid valves

Overall Dimension:

| Model | NC115-010-M4 | NC115-025-06 | NC115-025-08 | ||

| Working Medium | Air, Water, Oil | ||||

| Motion Pattern | Direct acting | ||||

| Type | Normal Close | ||||

| Orifice(mm) | 1.0 | 2.5 | |||

| VC Value | 0.10 | 0.23 | |||

| Connection Port | M4/M5 | 1/8'' | 1/4'' | ||

| Fluid Viscosity | <20CST | ||||

| Working Pressure(MPa) | Air, Water, Oil:0~0.7 | ||||

| Max. Pressure Resistance(MPa) | 1.2 | 1.6 | |||

| Working Temperature(℃) | -10~80℃ | ||||

| Voltage Range | ±10% | ||||

| Protection Class | IP65 | ||||

| Power Consumption | AC:5.5VA DC:6W | ||||

| Insulation Class | Class F | ||||

| Material of Body | Aluminum, Brass or S.S | ||||

| Seal | NBR or VITON | ||||

| Response Time | 0.05s | ||||

Product Details:

2 position 2/2-way Solenoid Valves usually includes valve body, spool, solenoid coil, spring and other components. The valve body is a container that holds the fluid, and the spool moves within the valve body to control the opening and closing of the channel. The solenoid is used to generate the driving force, and the spring is used to reset the spool when the solenoid is powered off.

Product Feature:

1. The structure is relatively simple, 2 position 2/2-way Solenoid Valves volume is relatively small, easy to install and integrate in various systems.

2. The 2 position 2/2-way Solenoid Valves response speed is fast, and the channel can be switched quickly to meet the requirements of high timeliness of control.

3. Accurate control: 2 position 2/2-way Solenoid Valves more accurate fluid on-off control can be achieved.

4. Compact size: takes up less space and is easy to install in a compact system.

Product Applications:

1. Pneumatic control system: 2 position 2/2-way Solenoid Valves used to control the intake and exhaust of the cylinder to achieve simple mechanical action.

2. Small hydraulic system: such as some simple machine tool hydraulic circuit, control the flow of hydraulic oil.

3. Refrigeration and air conditioning systems: regulate the flow of refrigerants.

4. Medical equipment: Control fluid turn-off in infusion, gas supply and other links.

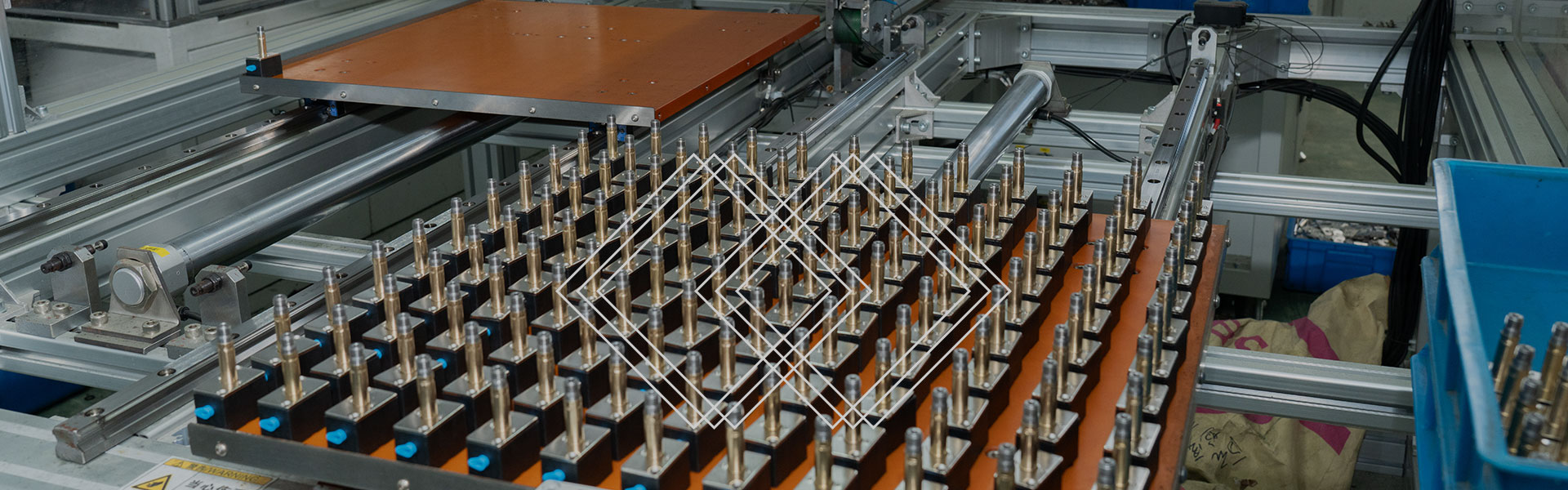

5. Simple fluid control on automated production lines: for example, quantitative delivery of paint, glue, etc.

6. Water treatment equipment: control the water in and out and the flow direction switch.