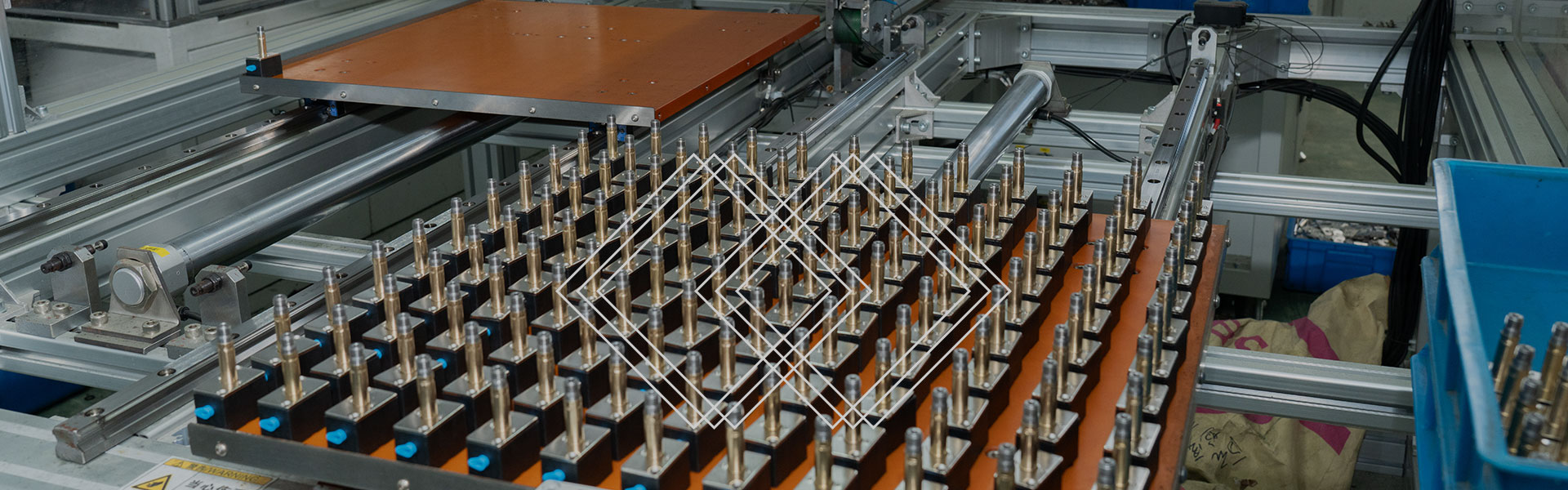

Armature Set

The Armature Set of the pneumatic component usually refers to the electromagnetic part of the pneumatic solenoid valve.

Send Inquiry

The pneumatic solenoid valve Armature Set has a closed chamber, and through holes are opened in different positions, each hole leads to a different air pipe. There are valves in the middle of the chamber and two electromagnets on both sides. When the magnet coil on one side is energized, the valve body is attracted to that side. Different vents are blocked or leaked by controlling the movement of the valve body, and the intake is usually normally open. In this way, the high-pressure gas will enter the different exhaust pipes, and then push the piston of the cylinder through the air pressure of the pneumatic solenoid valve, so as to achieve the control of the mechanical movement of the entire solenoid valve.

Specification

Product No.: NC603 3/2、NC604 2/2 Overall Dimension

Normally using 210A,3130 coil etc for matching 4V210 ,4V310,4V410 solenoid valves.

Details:

There are many kinds of classification of solenoid valves Armature Set, and the common ones are two two, two three, three two, three and so on. Different types of solenoid valves have different functions and application scenarios. In addition, the solenoid valve can also be selected according to different media (such as gas, liquid, etc.). When selecting a solenoid valve, some key factors need to be considered, such as the solenoid valve body material, sealing material, pressure resistance, etc., and the appropriate solenoid valve type and control mode need to be selected according to the specific application scenario.

In general, Armature Set are an important part of pneumatic solenoid valves, which can achieve accurate control of gas or liquid, improve production efficiency and automation level.

Product Feature:

1. Fast response speed: Armature Set can quickly realize the switch action and respond quickly to the control signal.

2. High control accuracy: the flow rate and pressure of the gas can be accurately controlled to meet the needs of various fine controls.

3. Strong reliability: the structure is relatively simple, the work is stable and reliable, and it can also operate normally under harsh working environment.

Applications:

1. Automatic production line: such as automobile manufacturing, electronic equipment production, etc., used to control the action of various pneumatic actuators.

2. Packaging industry: used for material conveying, sealing and other operations in packaging machinery.

3. Food and pharmaceutical industry: Control the operation of pneumatic equipment in environments with high hygiene requirements to ensure the safety and health of the production process.