Pilot Operated Valves

Send Inquiry

The Pilot Operated Valves are based on the interaction of electromagnetic force and fluid pressure.

When powered on, relying on the electromagnetic force to lift the valve stem, the pilot valve port is opened, at this time, the upper chamber of the solenoid valve through the pilot hole to relieve pressure, forming a high and low pressure difference around the main valve spool. Under the action of the pressure difference, the fluid pressure pushes the main valve spool upward to open the main valve port; When the power is off, under the action of spring force and main spool gravity, the valve stem is reset, the pilot hole is closed, the main spool moves down, the main valve port is closed, and the pressure of the upper chamber of the solenoid valve is increased, and the fluid pressure is pressurized to the main spool to make the seal better.

Product Specification:

Product No.: NC607 3/2、NC608 2/2

Normally using K23D-1.2 coil etc for matching K23D-1.2 Solenoid valves.

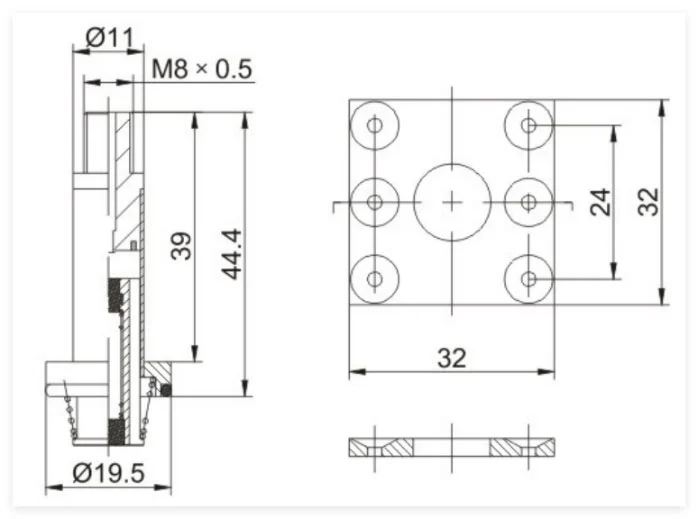

Overall Dimension:

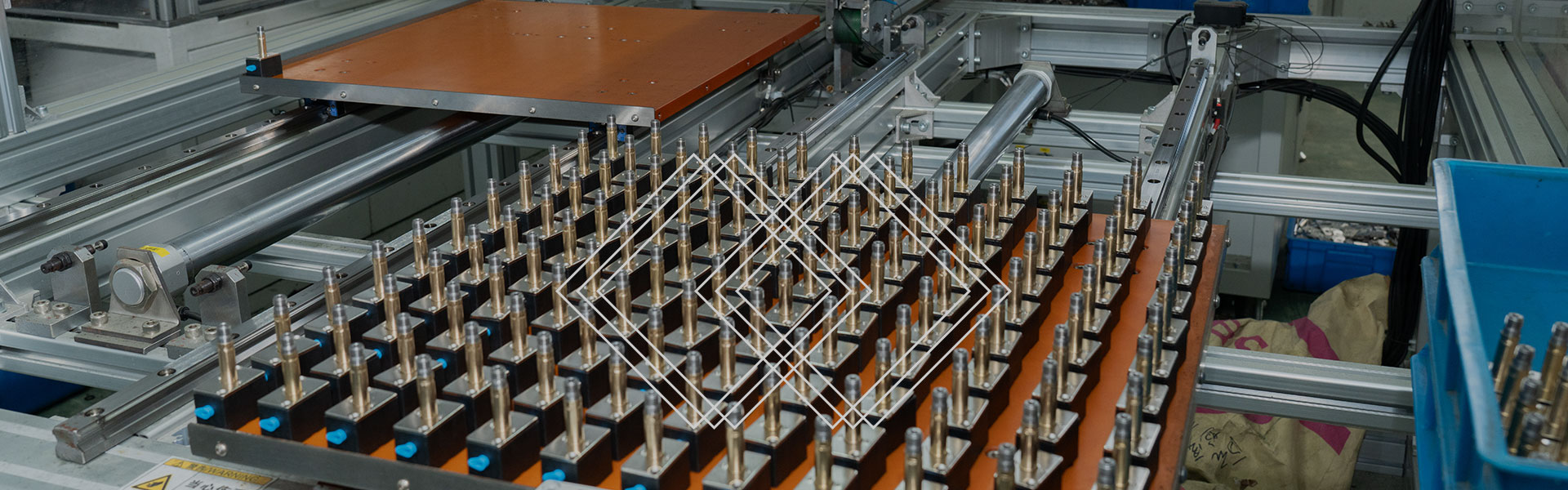

Product Details:

In practical applications, the medium of zero pressure difference or artesia state, small diameter is generally selected direct acting solenoid valve; There is a pressure difference before and after the valve, and the Pilot Operated Valves is usually used in the large diameter. Pilot Operated Valves is widely used in a variety of fluid flow control, level control, direction control, pressure control and other aspects, such as water treatment devices, pneumatic mechanical equipment, air conditioning equipment, automatic cleaning systems, hydraulic transmission systems. Especially in the need for frequent switching, high precision control flow occasions, pilot-operated solenoid valve can play a better performance.

Product Feature:

1. The upper limit of the fluid pressure range is high, and can be installed arbitrarily (need to be customized), but the fluid pressure difference conditions must be met;

2. Pilot diaphragm structure, low power consumption;

3. Protective diaphragm structure design, life extension twice;

4. The piping method can be installed at any Angle, in order to enhance the life, it is best to face up the horizontal pipe connection coil;

5. Coil protection grade is generally IP65.

Product Applications:

1. Industrial automation control system: Pilot Operated Valves used to control the flow, pressure and direction of various liquids and gases, such as in the production line of machinery manufacturing, chemical, petroleum, natural gas and other industries, to achieve accurate control of process media.

2. Refrigeration and air conditioning system: control the flow direction and flow of refrigerant, adjust the temperature and pressure of the system, and ensure the stable operation of the system.

3. Gas supply system: accurately control the on-off and flow of gas to ensure the safe operation of gas equipment, such as household gas furnaces and industrial gas burners.

4. Water treatment system: In the process of sewage treatment and water treatment, it is used to control the direction and flow of water flow to achieve automated water treatment process.

5. Hydraulic system: In the hydraulic transmission system of large mechanical equipment, it plays the role of regulating the flow direction and pressure of hydraulic oil.

6. Compressed air system: control the on-off and flow of compressed air to meet the working needs of different pneumatic equipment.