Electronic Drain Valves

Electronic Drain Valves utilize electronic control technology to precisely control the timing and frequency of drainage. They offer higher accuracy and reliability compared to traditional manual or mechanical drainage valves.

Send Inquiry

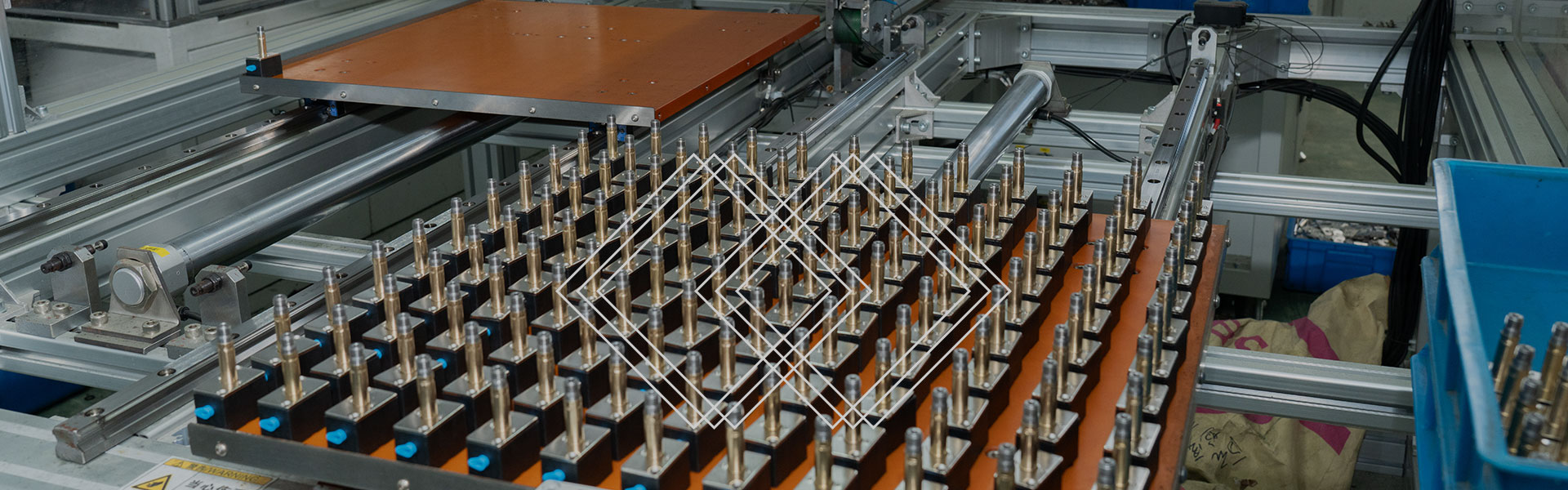

Electronic Drain Valves are typically composed of a valve body, a sensor, a controller, and an actuator. The sensor detects the presence of water or other fluids and transmits a signal to the controller. Based on the preset parameters and the signals received, the controller instructs the actuator to open or close the valve body, thereby realizing the drainage operation.

Product Feature:

1. High degree of automation: Electronic Drain Valves no need for frequent manual intervention, greatly saving labor costs and time.

2. Precise control: can accurately set the drainage interval, displacement and other parameters, to adapt to different application scenarios.

3. Strong reliability: the use of high-quality materials and advanced manufacturing processes to ensure long-term stable operation and reduce the probability of failure.

4. Energy saving and environmental protection: It avoids unnecessary drainage and effectively saves water resources and energy.

5. Easy installation and maintenance: compact structure, easy installation, and low daily maintenance requirements.

Electronic Drain Valves Applications:

Compressed air system: used to remove condensed water generated in compressed air, prevent moisture from causing damage to the equipment, improve the quality of compressed air and the operation efficiency of the equipment.

Industrial refrigeration system: timely discharge of condensate in the refrigeration equipment to ensure the normal refrigeration effect and stable operation of the system.

Air conditioning system: Whether it is central air conditioning or small air conditioning equipment, the electronic drainage valve can effectively deal with the condensate generated during the operation of air conditioning.

Steam system: help to eliminate condensate in steam pipes and equipment, prevent water hammer phenomenon and improve the heat transfer efficiency of steam.

Gas treatment system: for example, in the process of dry gas treatment, the generated water is discharged.

Industrial processing equipment: such as some need to cool or produce water vapor processing equipment, electronic drainage valve can ensure the normal operation of equipment and dry working environment.

Medical equipment: such as certain medical instruments that require precise control of humidity and drainage.

Food and beverage processing industry: used to treat the water generated in the processing process, maintain the health of the production environment and the normal operation of the equipment.

Specification:

Overall Dimension

| Model | NC-720 | ||

| Valves Style | Two-position two-way direct acting solenoid valves | ||

| Connection Port | 1/4'',3/8'',1/2'' (Female) | 1/8'' 1/4'' | |

| Working Pressure | 16bar, 25bar, 40bar,80bar | 16bar | |

| On Time | 0.5-10sec. | 1Sec~99h59min59Sec | 2 Sec |

| Off Time | 0.5~45min. | 1Sec~99h59min59Sec | 0.5~120min. |

| Ambient Temperature | -20~60℃ | ||

| Highest Medium Temperature | 90℃ | ||

| Valves Body | Brass, Stainless steel | ||

| Orifice | 1.9~4.5mm | 2mm | |

| Insulation, Protect Class | F class, IP65(with plug) | ||

| Voltage | 24-240V DC/AC 50/60Hz + 10% | ||

| Mounting | Any place | ||