Timer Drain with Integrated Strainer

Timer drain with integrated strainer is a device that integrates timing drainage function and filtering function together.

Send Inquiry

In the cooling system and lubrication system of industrial equipment, Timer drain with integrated strainer can regularly discharge the accumulated liquid and filter impurities to prevent damage to the equipment; In the water treatment system, it can be used for regular removal of wastewater or sediment, and preliminary filtration of water quality.

Product Specification:

Product No.: NCP-25

This series of Timer control drain valves are widely used in filters, separators, dryers, gas storage tanks, drip feet and other compressed air systems.

| Maxinum Compressor Capacity | Any Size |

| Pressure Range | 0-16bar, 0-40bar, 0-80bar(higher pressure available) |

| Supply Voltage Options | 12-380 VAC/DC 50/60Hz. (please indicate) |

| Medium Temperature | -20℃~60℃ |

| Timer Cycle Range(ON/OFF) | ON:0.5-10 seconds OFF:0.5-45 minutes |

| PCB Timer PCB | High quality PCB components, ensuring consistency inproduction |

| Timer Cycle Indication | Bright LED illumination |

| Test Feature | Yes |

| Valve Type | 2/2 way, direct acting |

| Valve Orifice | 4.5 mm, 2.5mm, 1.9mm |

| Valve Seals | FKM |

| Inlet/OutletConnections | 1/8", 1/4", 3/8", 1/2"(BSP, BSPT, NPT thread are available) |

| Valve Body Material | Brass orStainless steel |

| Power Connection | DIN 43650A |

| Environmental Protection | NEMA4(IP65) |

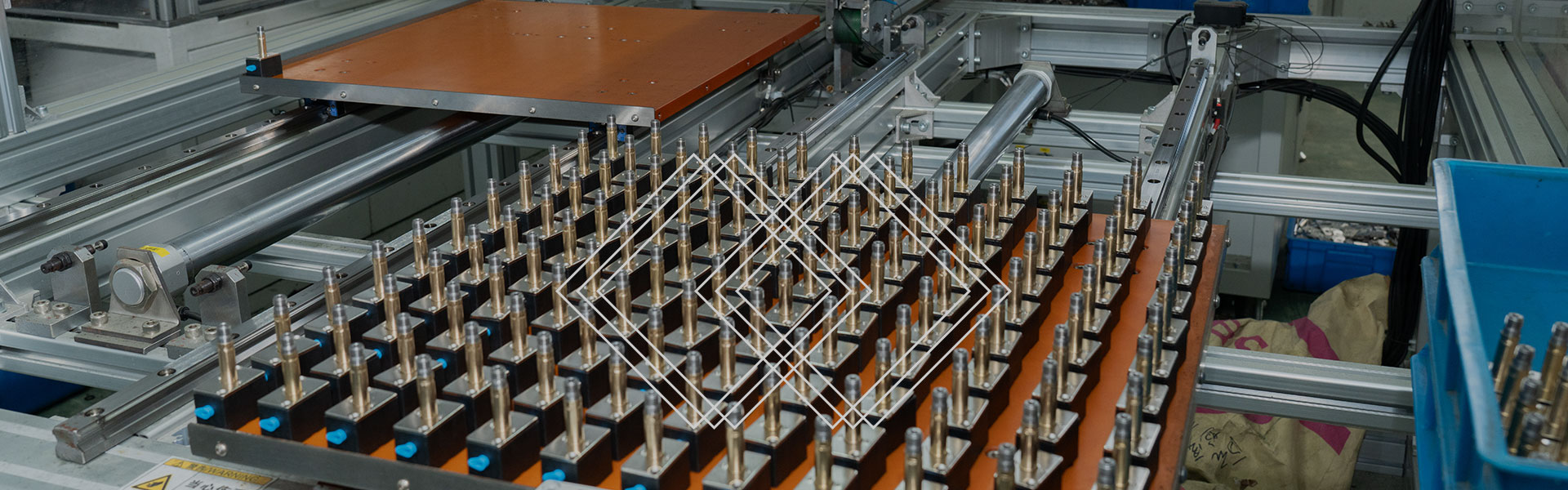

Product Details:

The Timer drain with integrated strainer working principle is to set the drainage time interval through the internal timer, when the set time is reached, the drainage valve automatically opens for drainage. At the same time, the integrated filter can effectively intercept impurities and particles as the liquid flows through, ensuring that the discharged liquid is relatively pure, reducing the impact on downstream systems or the environment.

Product Feature:

1. Periodic drainage function: Timer drain with integrated strainer can automatically discharge water at a preset time interval without manual intervention, saving manpower and ensuring the regularity of drainage.

2. Filtration function: Timer drain with integrated strainer can filter through the liquid to remove impurities, particles, etc., which helps to protect the normal operation of downstream equipment or systems.

3. Integrated design: The drainer and filter are integrated in one device, saving installation space and simplifying system layout.

Product Applications:

1. Industrial field: such as compressed air system, cooling circulation system, etc., can ensure the normal operation of the system and extend the service life of the equipment.

2. Air conditioning and ventilation system: discharge the condensate in time, and filter the dust and other impurities.

3. Water treatment system: In the process of water purification or sewage treatment, to achieve regular drainage and preliminary filtration.