Mini Push in Fitting

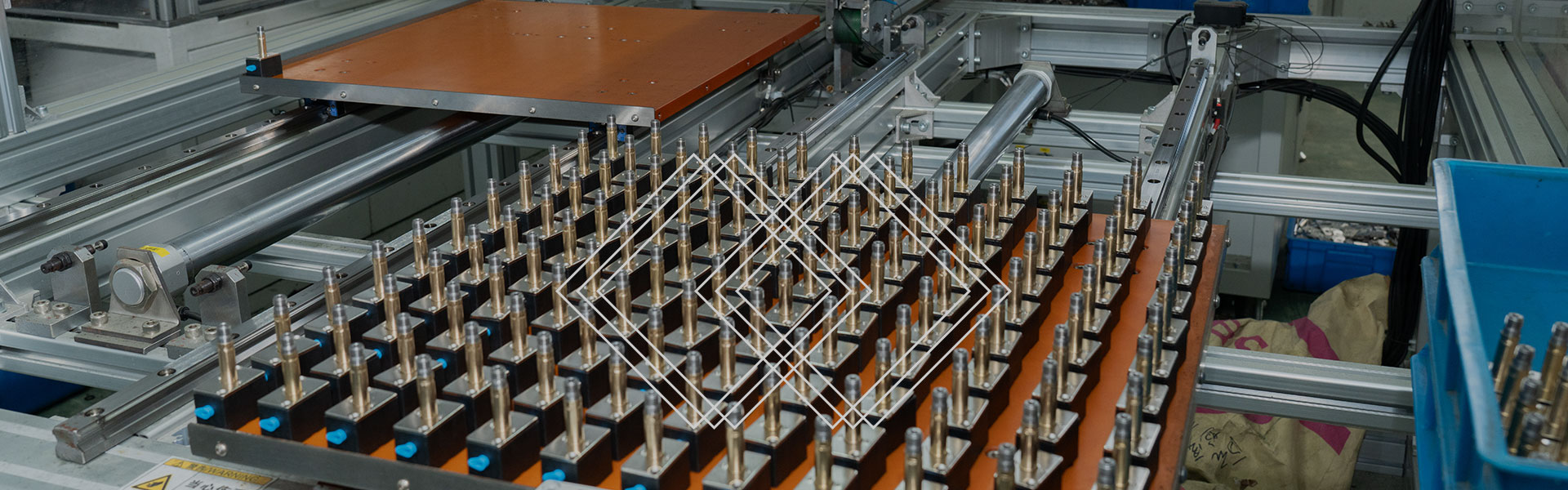

Mini push in fitting in the pneumatic component is a miniaturized connection component, which has an important role. Usually designed to be compact to accommodate space-limited pneumatic systems.

Send Inquiry

Product specification

| MODEL | φD | φD1 | φD2 | φD3 | L1 | L2 | L3 |

| QPY04 | 4 | 4 | 11.5 | 3.2 | 36.5 | 11 | 14.5 |

| QPY06 | 6 | 6 | 13.5 | 3.2 | 37.5 | 13 | 15 |

| QPY08 | 8 | 8 | 15 | 3.2 | 39.8 | 15 | 18 |

| QPY10 | 10 | 10 | 19 | 4.2 | 50 | 18 | 21 |

| QPY12 | 12 | 12 | 21.5 | 4.2 | 53 | 21 | 21.5 |

| QPY14 | 14 | 14 | 24 | 4.2 | 57 | 23 | 21 |

| QPY15 | 15 | 15 | 26.5 | 4.2 | 58.5 | 25 | 22 |

| QPY16 | 16 | 16 | 26.5 | 4.3 | 58.5 | 25 | 22 |

| QPY06-04 | 6 | 4 | 13.5 | 3.2 | 37.5 | 13 | 15 |

| QPY08-04 | 8 | 4 | 15 | 3.2 | 39.8 | 15 | 18 |

| QPY08-06 | 8 | 6 | 15 | 3.2 | 39.8 | 15 | 18 |

| QPY10-06 | 10 | 6 | 19 | 4.2 | 39.8 | 18 | 21 |

| QPY10-08 | 10 | 8 | 19 | 4.2 | 50 | 18 | 21 |

| QPY12-08 | 12 | 8 | 21.5 | 4.2 | 53 | 21 | 21.5 |

| QPY12-10 | 12 | 10 | 21.5 | 4.2 | 53 | 21 | 21.5 |

| QPY14-12 | 14 | 12 | 24 | 4.2 | 56 | 23 | 21 |

| QPY16-12 | 16 | 12 | 26.5 | 4.2 | 58.5 | 25 | 22 |

| QPY5/32 | 5/32 | 5/32 | 11.5 | 3.2 | 36.5 | 11 | 14.5 |

| QPY3/16 | 3/16 | 3/16 | 11.5 | 3.2 | 36.5 | 11 | 14.5 |

| QPY1/4 | 1/4 | 1/4 | 13.5 | 3.2 | 37.5 | 13 | 15 |

| QPY5/16 | 5/16 | 5/16 | 15 | 3.2 | 39.8 | 15 | 18 |

| QPY3/8 | 3/8 | 3/8 | 19 | 4.2 | 50 | 18 | 21 |

| QPY1/2 | 1/2 | 1/2 | 21.5 | 4.2 | 53 | 21 | 21.5 |

| QPY3/16-5/32 | 3/16 | 5/32 | 11.5 | 3.2 | 36.5 | 11 | 14.5 |

| QPY1/4-3/16 | 1/4 | 3/16 | 13.5 | 3.2 | 37.5 | 13 | 15 |

| QPY3/8-5/16 | 3/8 | 5/16 | 19 | 4.2 | 50 | 18 | 21 |

| QPY1/2-3/8 | 1/2 | 3/8 | 21.5 | 4.2 | 53 | 21 | 21.5 |

Product Details:

Mini push in fitting is mainly based on its special structural design and sealing mechanism.

Usually, such fittings contain an internal elastic sealing element, such as a rubber seal ring. When a pipe or other pneumatic element is inserted, the sealing element is squeezed, resulting in elastic deformation.

This deformation allows the sealing element to fit tightly to the inserted part, forming a good seal. This effectively prevents the gas from leaking from the joint, ensuring that the gas flows in the pneumatic system according to the predetermined path.

Product Feature:

1. Mini push in fitting easy to install: without complex tools and cumbersome operations, it can be quickly inserted and connected.

2. Good sealing: it can effectively prevent gas leakage and ensure the efficiency and stability of the system.

3. Miniaturized design: space saving, suitable for pneumatic equipment with high space requirements.

4. Excellent material: Usually made of high-strength, wear-resistant and corrosion-resistant materials to ensure long-term reliable use.

Product Applications:

Mini push in fitting are widely used in various small pneumatic tools, instruments and automation equipment gas path connection. They help simplify the layout of the system and improve the reliability and maintainability of the system.

Different types of mini insertion accessories may have specific structural and functional characteristics to meet different application needs. For example, some may have an anti-loosening design, and some may be suitable for high pressure or high temperature working environments.