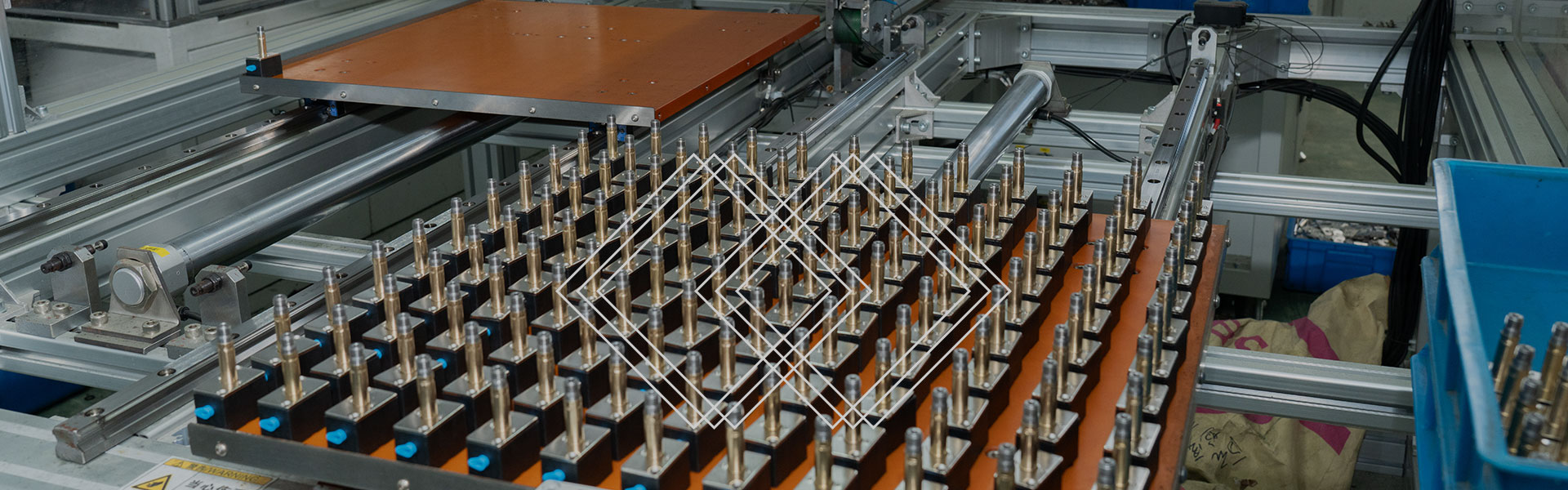

Pneumatic Push-in Fitting

Pneumatic push-in fitting, is an important part in the pneumatic system, which is used to connect and break the air circuit quickly.

Send Inquiry

Pneumatic push-in fitting is composed of a main body, a joint core, a seal, etc. The main body is generally made of metal or engineering plastic to provide a solid connection basis; The joint core is responsible for precise docking with the matching joint; Seals ensure good sealing after gas path connection, prevent gas leakage, commonly used rubber and other elastic materials made.

Product Specification:

| MODEL | φD | G | L1 | L2 | L3 | L4 | φD1 |

|

| NCM04-G01 | 4 | G1/8 | 5.5 | 25.5 | 44.5 | 19 | 11.5 | 14 |

| QPD04-G02 | 4 | G1/4 | 7.5 | 28 | 47 | 19 | 11.5 | 17 |

| QPD06-G01 | 6 | G1/8 | 5.5 | 25.7 | 44.9 | 19.2 | 13.5 | 14 |

| QPD06-G02 | 6 | G1/4 | 7.5 | 28.2 | 47.5 | 19.2 | 13.5 | 17 |

| QPD06-G03 | 6 | G3/8 | 7.5 | 28.7 | 48 | 19.2 | 13.5 | 20 |

| QPD06-G04 | 6 | G1/2 | 10 | 31.2 | 50.5 | 19.2 | 13.5 | 24 |

| QPD08-G01 | 8 | G1/8 | 5.5 | 29 | 51.5 | 22.5 | 15 | 14 |

| QPD08-G02 | 8 | G1/4 | 7.5 | 31.5 | 54. | 22.5 | 15 | 17 |

| QPD08-G03 | 8 | G3/8 | 7.5 | 32 | 54.5 | 22.5 | 15 | 20 |

| QPD08-G04 | 8 | G1/2 | 10 | 34.5 | 57 | 22.5 | 15 | 24 |

| QPD10-G01 | 10 | G1/8 | 5.5 | 34.5 | 63 | 27.8 | 19 | 17 |

| QPD10-G02 | 10 | G1/4 | 7.5 | 37 | 65.5 | 27.8 | 19 | 17 |

| QPD10-G03 | 10 | G3/8 | 7.5 | 37 | 65.5 | 27.8 | 19 | 20 |

| QPD10-G04 | 10 | G1/2 | 10 | 40.5 | 69 | 27.8 | 19 | 24 |

| QPD12-G01 | 12 | G1/8 | 5.5 | 36 | 65.5 | 29.5 | 21.5 | 21 |

| QPD12-G02 | 12 | G1/4 | 7.5 | 38.5 | 68 | 29.5 | 21.5 | 21 |

| QPD12-G03 | 12 | G3/8 | 7.5 | 38.5 | 68 | 29.5 | 21.5 | 21 |

| QPD12-G04 | 12 | G1/2 | 10 | 41.5 | 71 | 29.5 | 21.5 | 24 |

| QPD14-G03 | 14 | G3/8 | 7.5 | 39.5 | 66.5 | 27 | 23.5 | 22 |

| QPD14-G04 | 14 | G1/2 | 10 | 43 | 68.5 | 27 | 23.5 | 24 |

| QPD15-G03 | 15 | G3/8 | 7.5 | 42.5 | 75.5 | 33 | 26.5 | 24 |

| QPD15-G04 | 15 | G1/2 | 10 | 44 | 77 | 33 | 26.5 | 24 |

| QPD16-G03 | 16 | G3/8 | 7.5 | 42.5 | 75.5 | 33 | 26.5 | 24 |

| QPD16-G04 | 16 | G1/2 | 10 | 44 | 77 | 33 | 26.5 | 24 |

Product Feature:

1. Fast and convenient, Pneumatic push-in fitting complete the connection and disconnection of the gas path in a short time, effectively saving the time of installation, maintenance and equipment debugging.

2. Good sealing: the high quality sealing design the Pneumatic push-in fitting ensure that the gas does not leak under the specified pressure and maintain the stable operation of the pneumatic system.

Product Applications:

Pneumatic push-in fitting is widely used in all kinds of pneumatic equipment and systems, such as automatic production lines, pneumatic tools, automobile manufacturing, electronic equipment production and other fields, providing efficient and reliable gas path connection solutions for pneumatic transmission links in these industries.