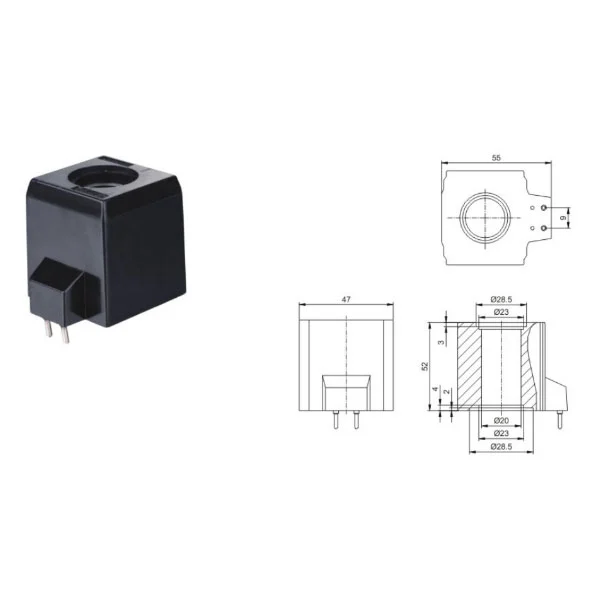

Hydraulic Solenoid Coil

Hydraulic Solenoid Coil is a key component in hydraulic components such as hydraulic solenoid directional valve. It generates a magnetic field through electrifying, so that the valve core moves, so as to control the flow direction of hydraulic oil, on and off, etc., to achieve different working states of the hydraulic system switch.

Send Inquiry

When a Hydraulic Solenoid Coil is energized, a magnetic field is generated inside the coil. This magnetic field will interact with the armature on the valve core, creating an electromagnetic suction force. Under the action of electromagnetic suction, the armature drives the valve core to move and change the connectivity of the oil channel inside the hydraulic valve, such as connecting or disconnecting the oil inlet and the oil outlet, or switching the connection relationship between different oil ports, in order to control the flow path of hydraulic oil in the system.

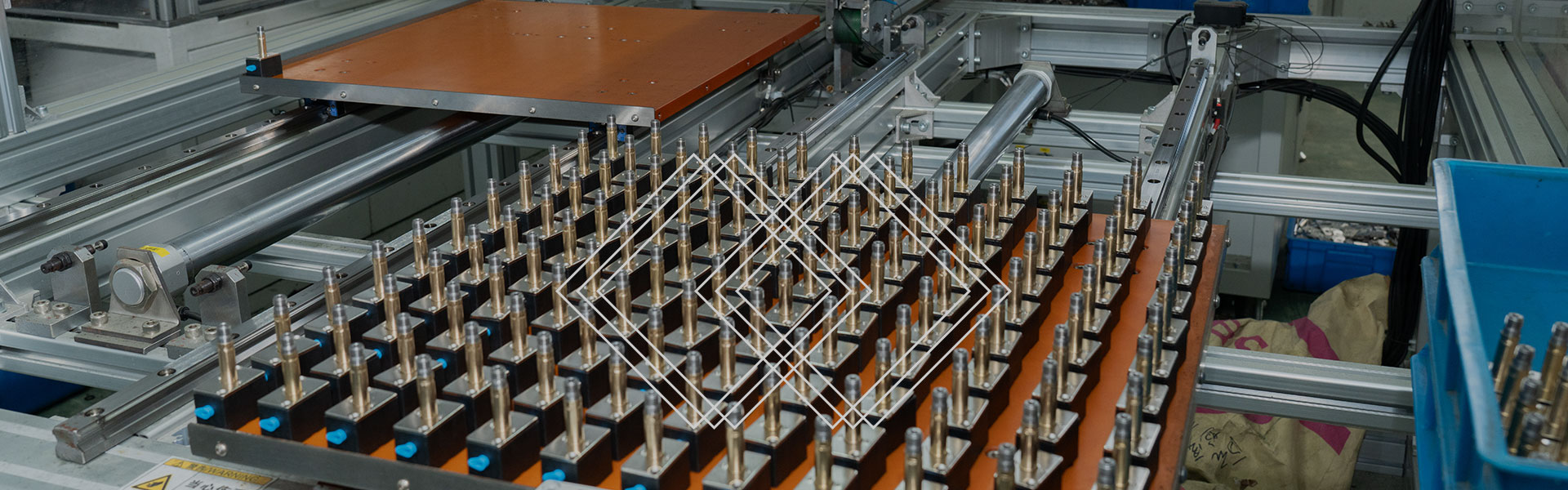

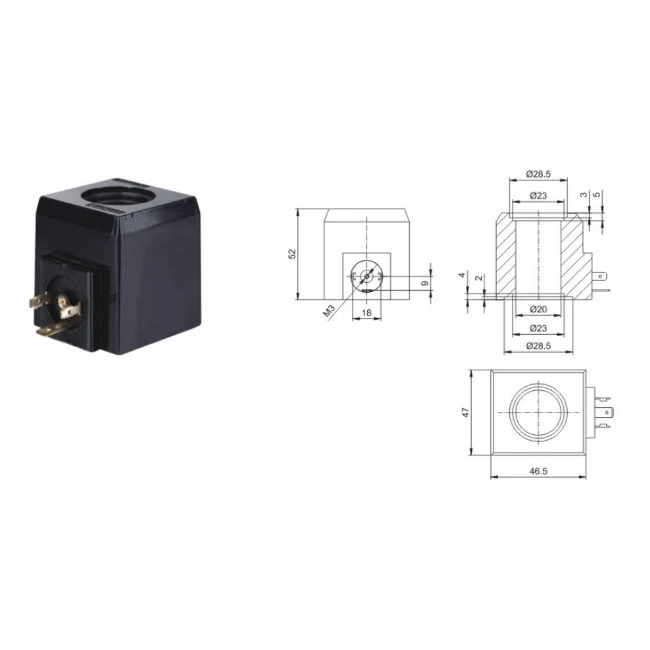

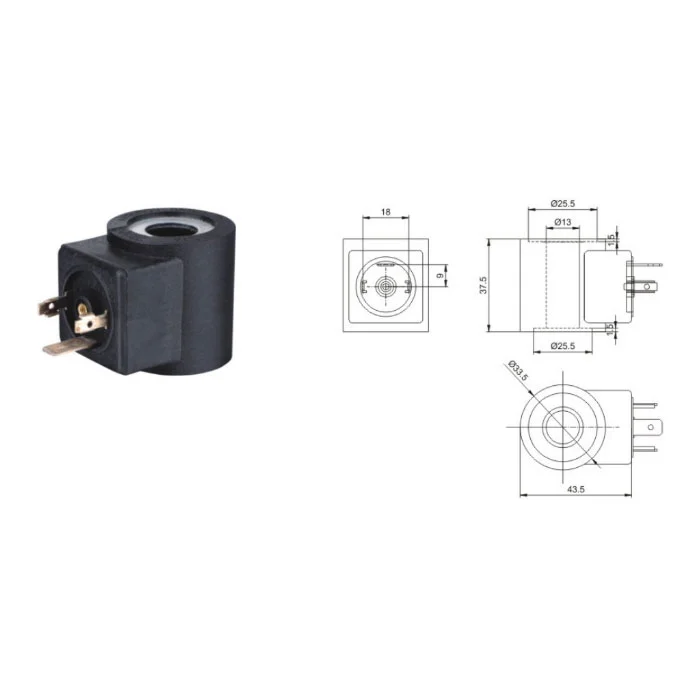

Specification

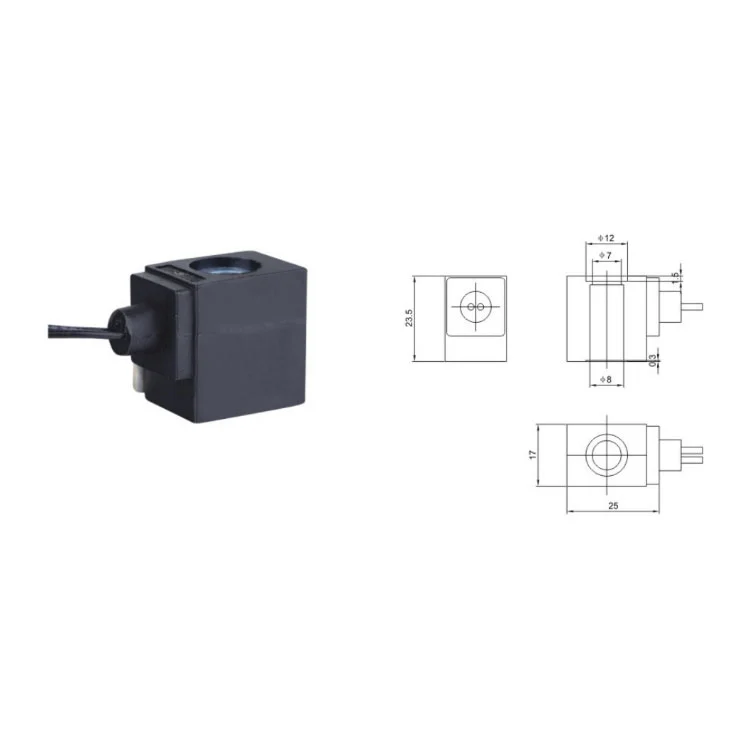

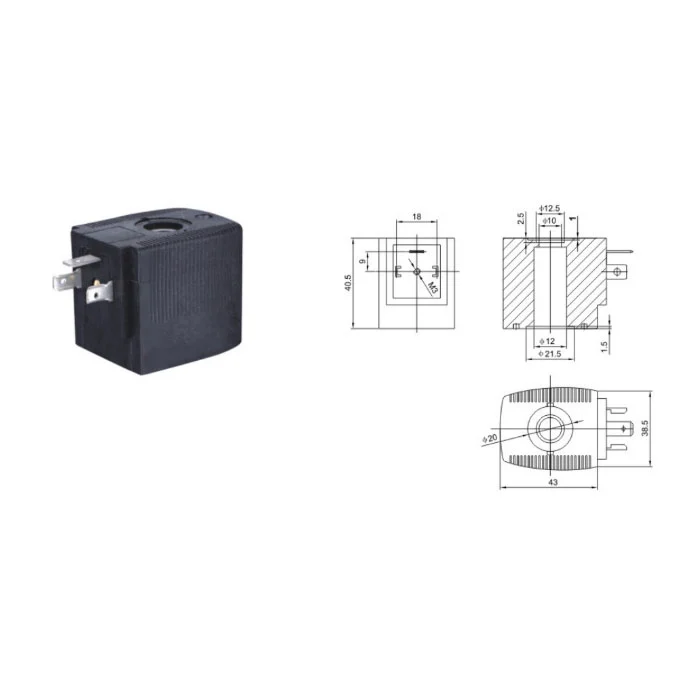

Product No.: NC098 Overall Dimension

| Normal Voltage | AC220V AC110V | |

| Normal Power | AC | 20VA |

| DC | ||

| Other voltage and power be customized | ||

| Insulation Class | H | |

| Connection type | DIN43650A | |

Details:

Hydraulic Solenoid Coil is generally composed of coil winding, iron core, skeleton and other parts. The winding of the coil is wound with insulated wire, which generates a magnetic field after being energized. The iron core is usually made of materials with good magnetic permeability, which can enhance the magnetic field strength; The skeleton supports the winding of the coil and ensures good insulation between the winding and the iron core.

Product Feature:

1. Accurate control: Hydraulic Solenoid Coil can accurately control the spool action according to the electrical signal instruction to achieve accurate oil circuit control of the hydraulic system.

2. Fast response speed: After power-on, enough magnetic field can be generated in a short time to make the spool move and complete the state switch.

3. Remote control: Through electrical signal transmission, the hydraulic valve can be controlled at a long distance, which is convenient for system layout and operation.

Applications:

Construction machinery: such as excavators, loaders, etc., the hydraulic system is controlled by hydraulic electromagnetic coils to realize the extension of the digging arm, the opening and closing of the digging bucket, and the steering and braking of the vehicle, so as to improve the working efficiency and operation accuracy of the machinery.

Automotive engineering: used for shift control of automatic transmission, hydraulic control of brake system and power control of steering system, etc., to ensure smooth operation and safety performance of the car.

Machine tool equipment: In the hydraulic transmission system of the machine tool, the opening and closing of various valves are controlled to achieve the feed of the workbench, the clamping and loosening of the tool, the transmission of the spindle and other functions to improve the machining accuracy and automation of the machine tool.

Metallurgical equipment: such as steel mill rolling machine, continuous casting machine, etc., control the hydraulic cylinder and hydraulic motor in the hydraulic system, accurately adjust the spacing of the rolls, control the conveying speed of the casting billet, etc., to ensure the stability of the production process and product quality.