No Encapsulation Coils

No Encapsulation Coils usually refers to the solenoid valve coil and other components used in the pneumatic system. No Encapsulation Coils main role is to convert electrical energy into magnetic field energy to control the switch of pneumatic valves and other components.

Send Inquiry

No Encapsulation Coils usually consists of wires wound around an iron core without the outer protection of a plastic package. The working principle is that when the current passes through the wire, a magnetic field is generated, which drives the associated pneumatic components.

Structurally, the non-plastic design makes it more open, which may help heat dissipation, but it is also relatively more susceptible to external environmental factors, such as dust, moisture, and so on.

Specification

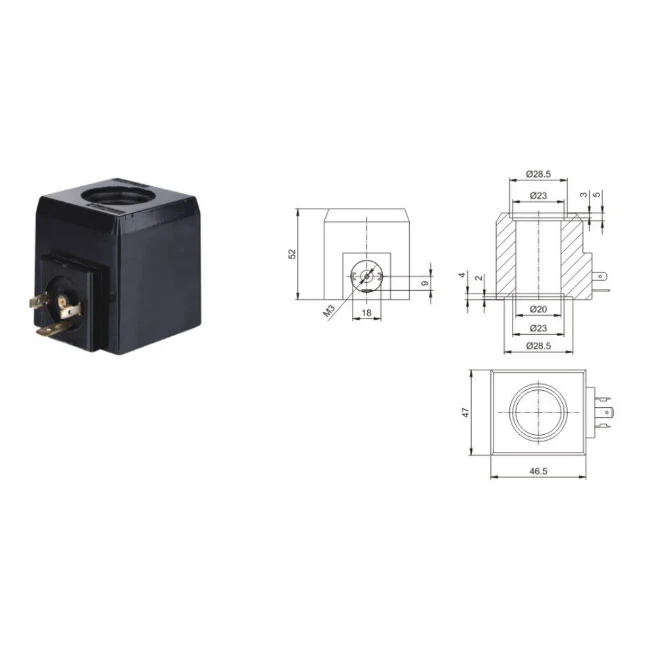

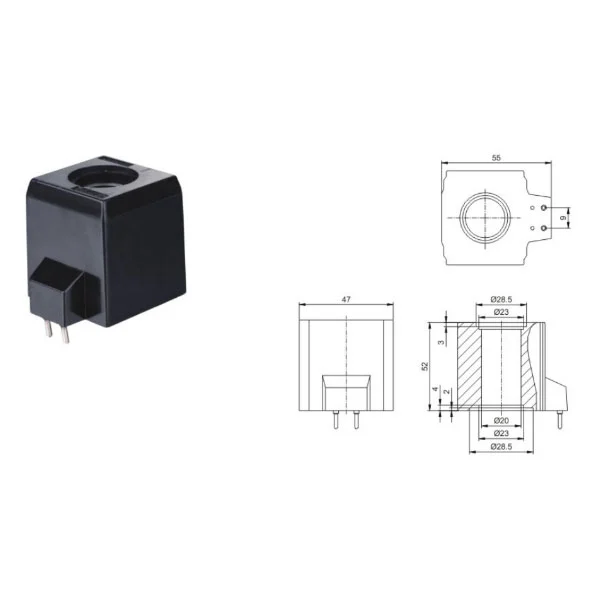

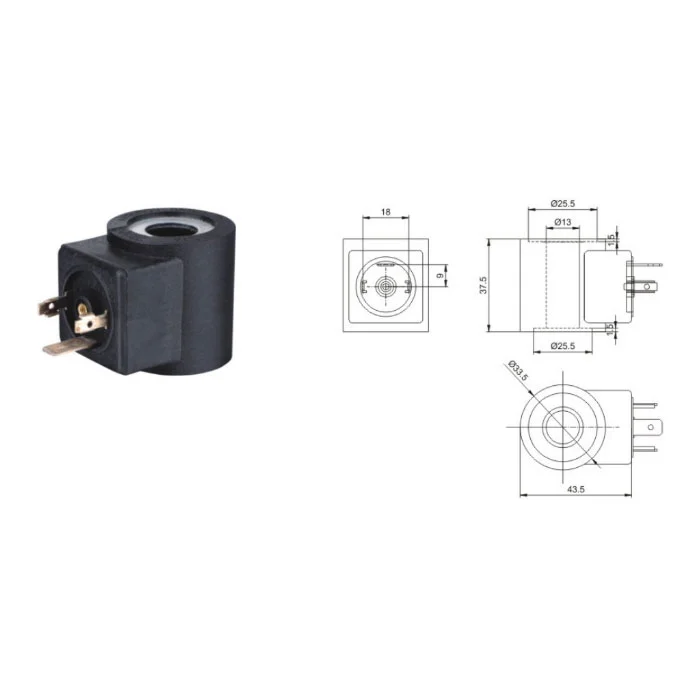

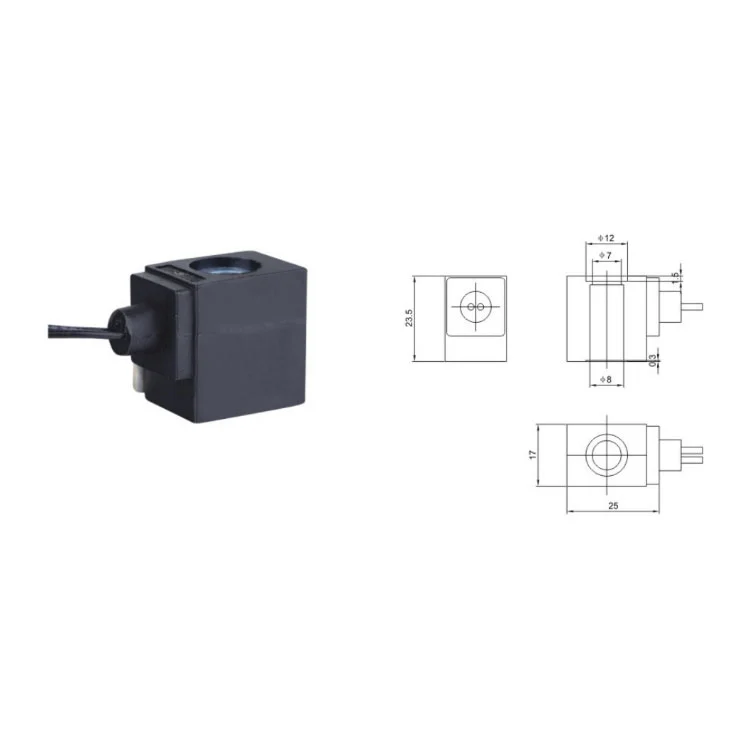

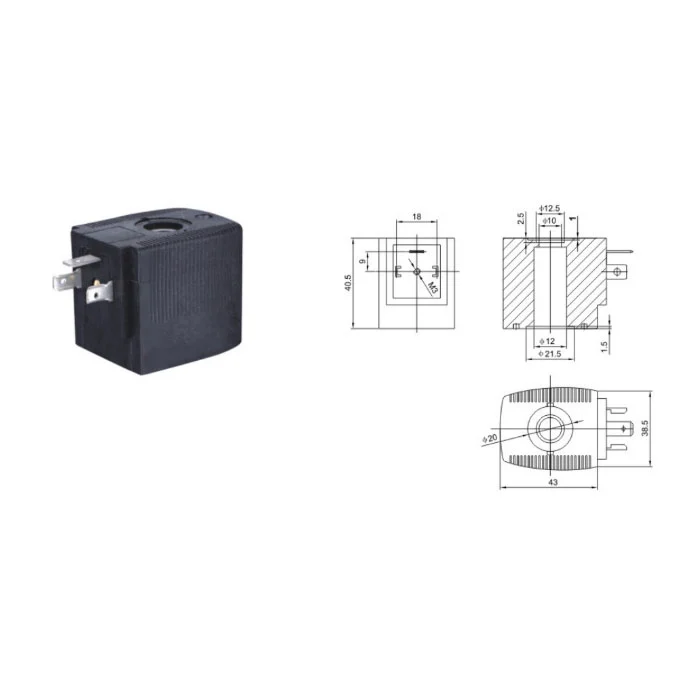

Product No.: NC953 Overall Dimension

| Normal Voltage | ||

| Normal Power | AC | |

| DC | ||

| Other voltage and power be customized | ||

| Insulation Class | H | |

| Connection type | 4.8x0.5 | |

Details:

To ensure the No Encapsulation Coils normal operation and service life of pneumatic non-plastic sealed coils, the following points need to be noted:

Correct selection: According to the actual conditions and requirements, select the appropriate specifications and parameters of the coil.

Quality assurance: Choose products with reliable quality to avoid failures or safety hazards caused by quality problems.

Prevention of corrosion: Consider the corrosive factors in the use of the environment, take appropriate protective measures.

Regular inspection: including checking the appearance of the coil and whether the connection is good.

Pay attention to heat dissipation: Although there is no plastic package, it is still necessary to ensure that the coil does not overheat when working to prevent affecting performance and life.

Product Feature:

1. Good heat dissipation performance: No Encapsulation Coils without the block of plastic packaging, heat can be dissipated more quickly, which helps to maintain a lower temperature during the working process, thereby improving the stability and service life of the coil.

2. The cost is relatively low: the simplified structure and less packaging materials make No Encapsulation Coils manufacturing cost lower than that of the plastic sealed coil.

3. More direct electromagnetic response: without the barrier of plastic, the electromagnetic effect can be played more directly, which may have certain advantages in response speed and control accuracy.

4. High flexibility: It has greater flexibility in installation and layout, and is easier to adapt to different space and structural requirements.

Applications:

1. General industrial pneumatic control: such as some simple pneumatic valves, cylinder control, in the case of low protection requirements and strict cost control.

2. Small pneumatic tools: such as small pneumatic screwdrivers, spray guns, etc., the working environment of these tools is relatively good, and the protection requirements for coils are not high.

3. Temporary or simple pneumatic systems: In some temporary pneumatic systems with low frequency of use, non-plastic-sealed coils can meet basic functional requirements while reducing costs.

4. Well-ventilated equipment: used in equipment that has good ventilation conditions and can effectively reduce the impact of the environment on the coil.