Metal Silencer

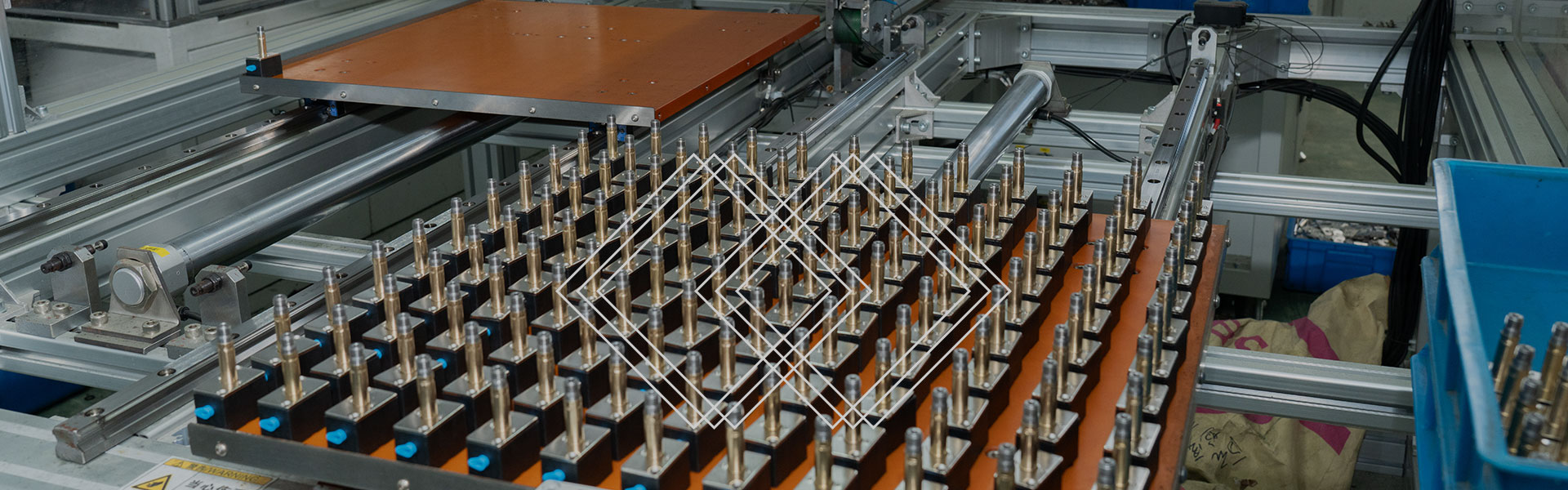

Metal silencer in a pneumatic element is a device used to reduce the noise of gas emissions in a pneumatic system.

Send Inquiry

Metal silencers are usually made of metal materials and have good durability and high temperature resistance. Metal silencers working principle is mainly through the internal structural design, such as porous materials, expansion chambers, resonators, etc., to change the flow characteristics of the gas, so as to reduce the energy of the noise.

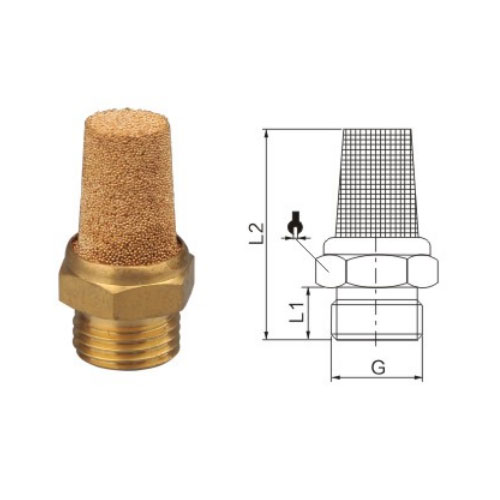

Product Specification:

| Models | G | L1 | L2min | L2max |

| NCS-G01 | G1/8 | 6 | 21 | 23 |

| NCS- G02 | G1/4 | 7.5 | 25.5 | 28 |

| NCS-G03 | G3/8 | 9 | 30.5 | 33 |

| NCS-G04 | G1/2 | 10.5 | 34.5 | 37.5 |

| NCS-G06 | G3/4 | 11 | 45 | 50 |

| NCS-G10 | G1 | 14 | 52 | 57 |

Product Details:

In the pneumatic system, such as the exhaust process of the cylinder, the high-speed flow of gas often produces a large noise. The use of metal silencers can effectively reduce this noise, which not only helps to improve the working environment, but also reduces the impact of noise on the surrounding environment.

The performance indicators of metal silencers usually include silencing effect, pressure loss, applicable working pressure and temperature range. Different types and specifications of metal silencers are suitable for different pneumatic application scenarios to meet the noise control and performance requirements of the system.

Product Feature:

Good noise reduction effect: using the anti-spray, resistance compound noise reduction principle, large noise reduction, can effectively reduce the noise generated by the exhaust gas of pneumatic components, such as all copper particles sintered silencer, etc., can greatly reduce the noise value.

Small pressure loss: the exhaust resistance is small, no impact on the machine action, to ensure the normal operation of pneumatic components, maintain the stability of the system pressure, to ensure that the performance of the equipment is not affected.

Product Applications:

Industrial manufacturing: widely used in power generation, chemical industry, metallurgy, textile and other industrial factories and mines, such as various types of boilers, turbine exhaust steam, fans, safety doors and other equipment, reduce the noise of equipment operation, improve the working environment, protect the hearing health of workers.

Automobile manufacturing: Used in pneumatic equipment on automobile production lines, such as pneumatic wrenches, pneumatic fixtures, etc., to reduce noise pollution, while ensuring the normal operation of equipment, to ensure production quality and efficiency.