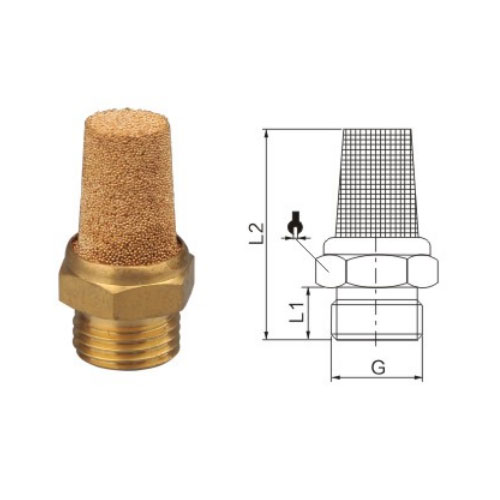

Plastic Muffler Silencer

Welcome to buy our Qimao Pneumatic products. Plastic Muffler Silencer are usually made of engineering plastics, such as PC, PA, etc., which have advantages in application scenarios with strict requirements for weight compared to metal mufflers.

Send Inquiry

The Plastic Muffler Silencer interior contains a series of specially designed channels and chambers, the shape, size and connection of which are carefully designed to achieve effective noise reduction during the operation of pneumatic tools.

Product Feature:

1. Light weight. The Plastic Muffler Silencer material is much less dense than the metal material, so that when installed on the pneumatic tool, it will not add too much weight.

2. Diverse shape design. The plastic molding process allows the muffler to be made into a variety of shapes to match a variety of special-shaped tools to achieve better installation effects and aesthetics.

3. Easy to install, cause of Plastic Muffler Silencer light weight, simple structure, the process of plastic installation is very convenient, and the maintenance work is relatively simple.

Product Applications:

Car maintenance, in the process of car maintenance, such as the pneumatic spray gun used during cleaning will produce noise in the exhaust process, and the plastic muffler can reduce the noise.

Furniture manufacturing industry, in the woodworking workshop, the moving tool is indispensable, the plastic muffler installed on the corresponding tool, can effectively reduce the noise, and its light weight, will not increase too much weight, convenient for workers to operate.

Electronic equipment manufacturing workshops, in some noise-sensitive operating environments, such as precision electronic components assembly, installation of Plastic Muffler Silencer can reduce noise and ensure that workers work accurately in a quiet environment.

Product Specification:

| Models | G | ΦD | L1 | L2 |

| NCP-G01 | G1/8 | 13 | 6 | 30 |

| NCP-G02 | G1/4 | 17 | 7 | 36 |

| NCP-G03 | G3/8 | 25 | 10 | 64 |

| NCP-G04 | G1/2 | 25 | 10 | 67 |

| NCP-G06 | G3/4 | 37 | 15 | 137 |

| NCP-G10 | G1 | 48 | 18 | 155 |