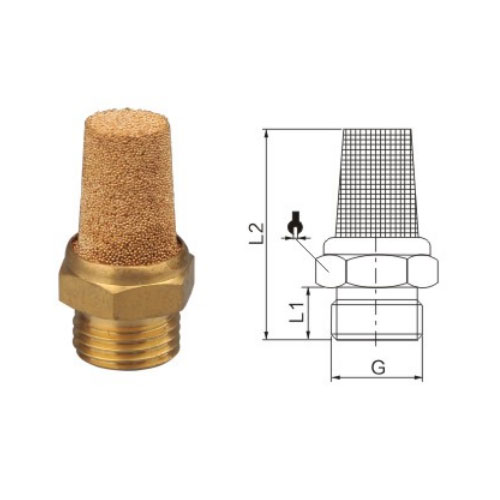

Pneumatic Plastic Muffler

Send Inquiry

Pneumatic Plastic Muffler mainly made of high-quality plastic materials, using the characteristics of plastic to achieve sound suppression function. Plastic has a certain elasticity and sound-absorbing ability, which can reduce the propagation and reflection of sound waves to a certain extent.

In terms of structure, plastic silencers usually have complex channels, pores or sound-absorbing materials inside. As the gas passes through these structures, the energy of the sound waves is gradually dissipated and dispersed, reducing the intensity and frequency of the noise.

Product Specification:

| Models | G | ΦD | L1 | L2 |

| NCS-G01 | G1/8 | 16 | 7 | 32 |

| NCS-G02 | G1/4 | 20 | 8 | 42 |

| NCS-G03 | G3/8 | 24 | 10 | 56 |

| NCS-G04 | G1/2 | 24 | 10 | 56 |

| NCS-G06 | G3/4 | 48 | 17 | 134 |

| NCS-G10 | G1 | 48 | 17 | 134 |

Product Details:

Pneumatic Plastic Muffler utilizes the characteristics of plastic, combined with the ingenious internal structural design, effectively reduces the noise generated by gas emissions during the operation of the pneumatic system. Plastic has certain sound-absorbing and shock-absorbing properties, which can weaken the energy of sound waves to a certain extent.

Such silencers usually have circuitous channels, porous structures, or sound-absorbing materials inside. When a high-speed flowing gas passes through, sound waves are constantly refracted, reflected, and absorbed in complex internal structures, significantly reducing the intensity and frequency of noise.

Product Feature:

1. Pneumatic Plastic Muffler is lightweight, easy to install and maintain.

2. Pneumatic Plastic Muffler does not add too much burden to the pneumatic system.

3. Plastics have good corrosion resistance and can maintain stable performance in harsh environments such as moisture and chemicals.

4. In addition, the relatively low cost of plastic materials helps to reduce the overall cost

Product Applications:

1. Light industrial production: for example, pneumatic equipment in textile, garment manufacturing and other industries, these scenes are more sensitive to the weight and cost of equipment, and the lightweight and economic advantages of plastic silencers can be better played.

2. Food and drug processing: due to its good corrosion resistance and non-polluting products, it is suitable for use in pneumatic tools and equipment on food and drug production lines with high hygiene requirements.

3. Electronic manufacturing: In the assembly and production process of electronic products, the noise generated by pneumatic devices may affect product quality and worker operation, plastic silencer can effectively reduce noise, while its insulation performance can also avoid interference with electronic components.