Pneumatic Plastic Silencer

Pneumatic Plastic Silencer is a device used to reduce the noise generated by gas flow in a pneumatic system. It is made of plastic material, through special structural design and internal construction to absorb, reflect and disperse sound waves, so as to achieve the purpose of reducing noise transmission.

Send Inquiry

Pneumatic Plastic Silencer play an important role in pneumatic systems where noise needs to be controlled and operating conditions are relatively mild, providing an effective solution for quiet and comfortable working environments.

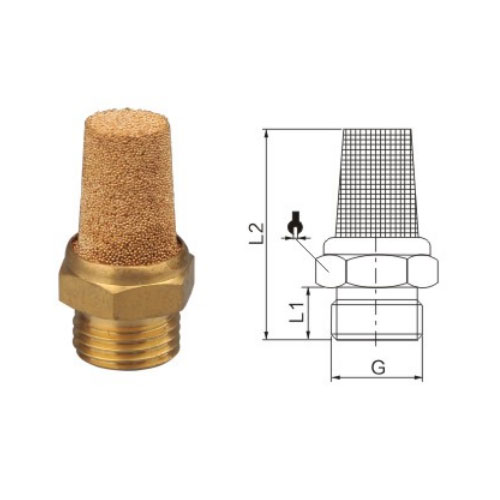

Product Specification:

| Models | G | ΦD | L1 | L2 | B |

| NCSP-M5 | M5 | 8.5 | 5 | 18 | 0.9 |

| NCSP-G01 | G1/8 | 16 | 6.5 | 40 | 1.3 |

| NCSP-G02 | G1/4 | 21 | 10 | 65 | 1.3 |

| NCSP-G03 | G3/8 | 25 | 12.5 | 85 | 1.5 |

| NCSP-G04 | G1/2 | 30 | 14 | 94 | |

| NCSP-G06 | G3/4 | 45 | 16 | 100 | |

| NCSP-G10 | G1 | 45 | 17 | 100 |

Product Details:

Pneumatic Plastic Silencer are usually installed at the exhaust ports of pneumatic components, such as cylinders, pneumatic valves, etc., to suppress high-frequency noise generated when gas is emitted. Its appearance and shape may vary depending on the specific application and design requirements, but it generally has an air intake and an air outlet, and contains a sound absorbing material or a special channel structure.

Compared with traditional metal silencers, plastic silencers have the advantages of light weight, relatively low cost, and good corrosion resistance. However, in some applications where high pressure, high temperature or high strength requirements are required, the performance of plastic silencers may not be as good as metal silencers.

Product Feature:

1.Durability: Pneumatic Plastic Silencer usually made of wear-resistant, corrosion-resistant materials, able to operate stably for a long time under harsh working conditions.

2. Strong adaptability: Pneumatic Plastic Silencer can adapt to different working pressure and flow range, to meet the needs of a variety of pneumatic systems.

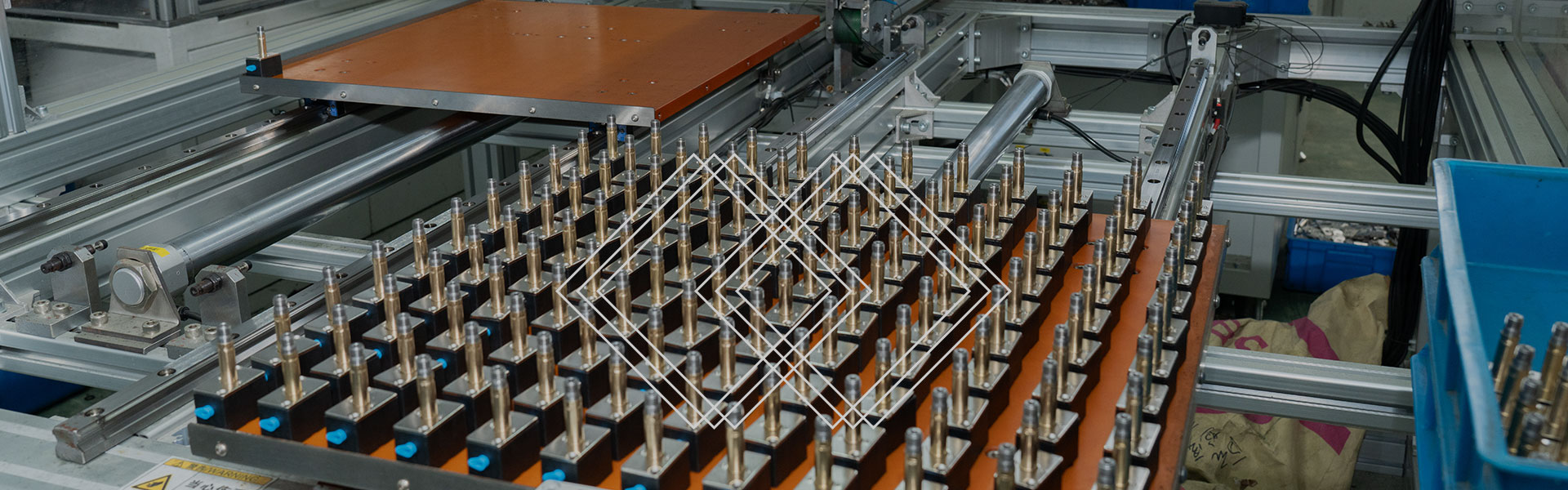

Product Applications:

1.Electronic manufacturing: In the assembly process of electronic products, reduce the noise interference of pneumatic equipment.

2. Aerospace field: Control noise generated by pneumatic tools in aircraft maintenance and manufacturing.

3. Printing industry: all kinds of pneumatic driven printing equipment to reduce the impact of noise on operators.