Pneumatic Coils

Pneumatic Coils are a key component used to control pneumatic valves in pneumatic systems. Through electromagnetic conversion, a magnetic field is generated when the current passes through the valve core to move, thereby controlling the gas flow. It has the characteristics of efficient electromagnetic conversion, durability, stability, etc., and has a variety of specifications to adapt to different pneumatic solenoid valves.

Send Inquiry

Pneumatic Coils are usually a part of the electromagnetic device used to control the on-off action of the pneumatic valve. When the current passes through the coil, a magnetic field is generated, and the action of the magnetic field causes the spool in the valve to move, thereby changing the channel of the air flow and realizing the control of the gas flow.

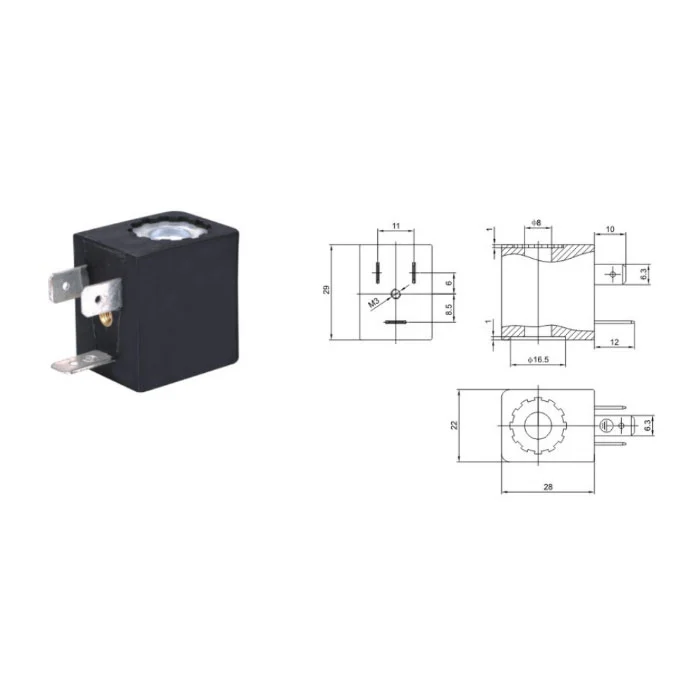

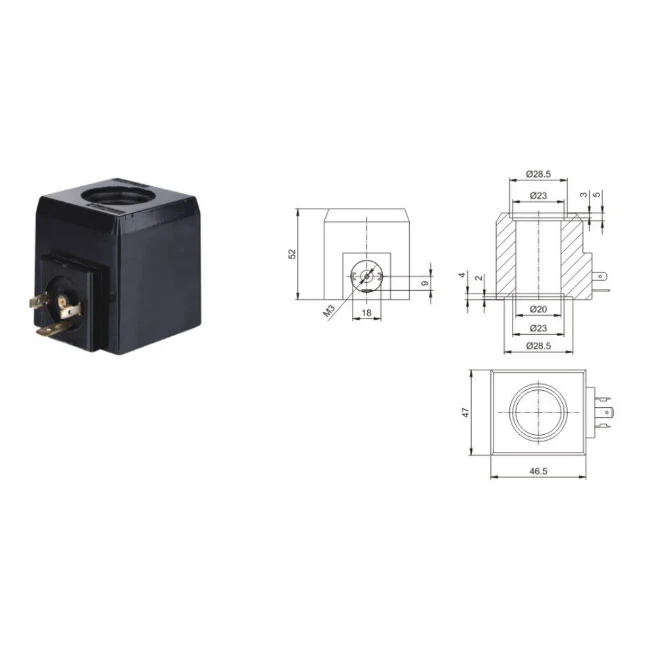

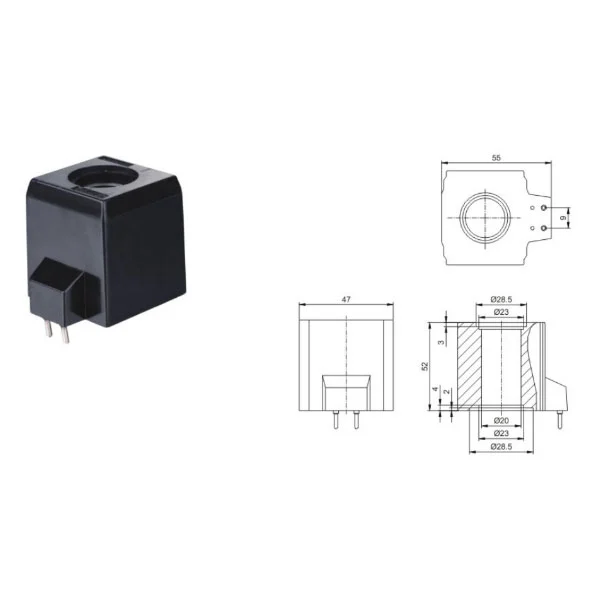

Specification Of Pneumatic Coils

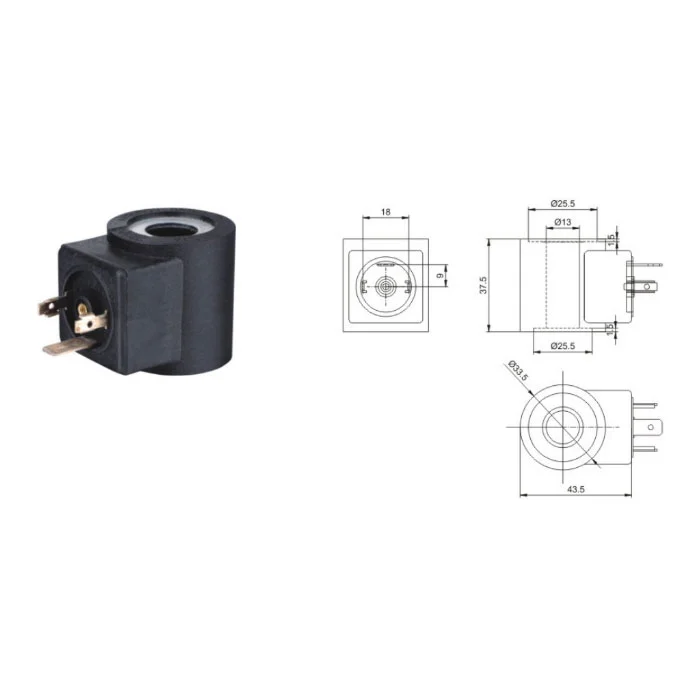

Item No: NC052 Overall Dimension

| Normal Voltage | AC220V AC110V DC24V | |

| Normal Power | AC | 6.5VA |

| DC | 3W 5.5W 6W | |

| Other voltage and power be customized | ||

| Insulation Class | B、 F、 H | |

| Connection type | DIN43650B | |

Pneumatic Coils Details:

Pneumatic coils by efficient electromagnetic conversion, durability, stability, etc., and has a variety of specifications to adapt to different pneumatic valves.

Product Feature:

1. Fast response: Pneumatic Coils can react to current changes in a short time to achieve rapid control of pneumatic components.

2. Precise control: Pneumatic Coils can precisely control the movement of the spool, so as to achieve accurate adjustment and control of the air flow.

3. Strong durability: Usually using high-quality insulating materials and winding process, with good heat resistance, wear resistance and corrosion resistance, able to operate stably in harsh working environments for a long time.

4. Low energy consumption: The energy consumption in the working process is relatively low, which helps to reduce the overall energy consumption of the system.

5. Compact structure: small size, easy to install in the compact space of the pneumatic system.

6. Good versatility: It can be used with a variety of different types and specifications of pneumatic valves, with strong versatility and compatibility.

7. High reliability: After strict quality detection and testing, it has high reliability and stability, reducing the probability of failure.

Applications:

1.Industrial automation production line: Pneumatic Coils used to control various actuators and valves to achieve automatic control of the production process.

2.Printing machinery: pneumatic Coils components that accurately control paper transfer and printing pressure.

3.Food and beverage processing industry: pneumatic valve control for filling, packaging and material handling.

4.Plastic molding machinery: control mold opening and closing, blowing and demolding. Electronic manufacturing equipment: pneumatic op